Engineering Challenges.

Solved Cleverly.

Cedar Consulting provides expertise in Mechanical Design and Engineering with hands-on experience across the entire project lifecycle.

From concept development to production. With over a decade of expertise and a patented design, I turn your ideas into functional, manufacturable solutions.

From products, mechanical appliances to packaging and furniture. We provide precise, reliable CAD designs that are manufacturing ready.

We can assist with finding the right manufacturing partners, while keeping the overall budget in mind.

Let’s bring your vision to life with smart, efficient engineering.

Services

From detailed 3D models to exact drawings and hands-on concept support, we make sure your project moves smoothly from idea to manufacturing.

-

Create precise 3D models for components of any complexity.

Solid body modeling for complex geometries

Sheet metal design

Welded metal structures

Plastic parts for injection molding

-

Deliver clear, production-ready documentation.

2D manufacturing drawings (DWG, DXF, PDF)

Compliance with client technical specifications

Inclusion of BOMs and full manufacturing details

-

Turn ideas into actionable technical plans.

Draft initial concepts and requirements

Develop multiple design options

Collaborate closely for iterative improvement

Project Workflow

From idea to production-ready solution, each project is guided through a proven, step-by-step workflow:

1. Discover & Define

We align with your team to understand technical requirements, constraints, and goals. This foundation guides everything that follows.

2. Concept & Approval

We explore different design directions, develop initial concepts, and present variations. Once approved, the concept is locked in.

3. Design & Engineering

We build detailed SolidWorks models, designed for real-world function, performance, and manufacturability.

4. Prototyping & Support

We assist with prototype production and help source the right manufacturing partner. Feedback leads to refinements and a second prototype if required.

5. Final Design & Documentation

Once the design is finalized, we deliver complete 2D manufacturing drawings and assembly documentation.

6. Project Handover

You receive all final files, CAD models, drawings, and support to move smoothly into production.

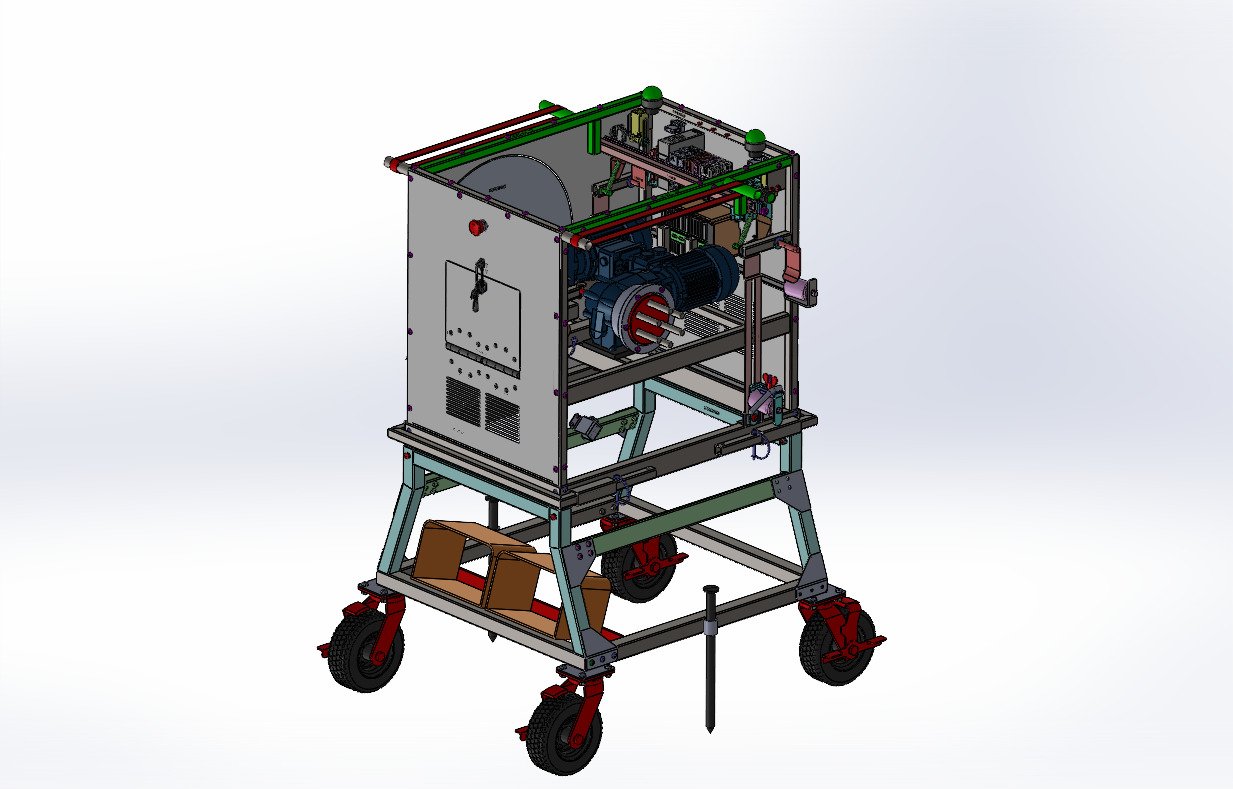

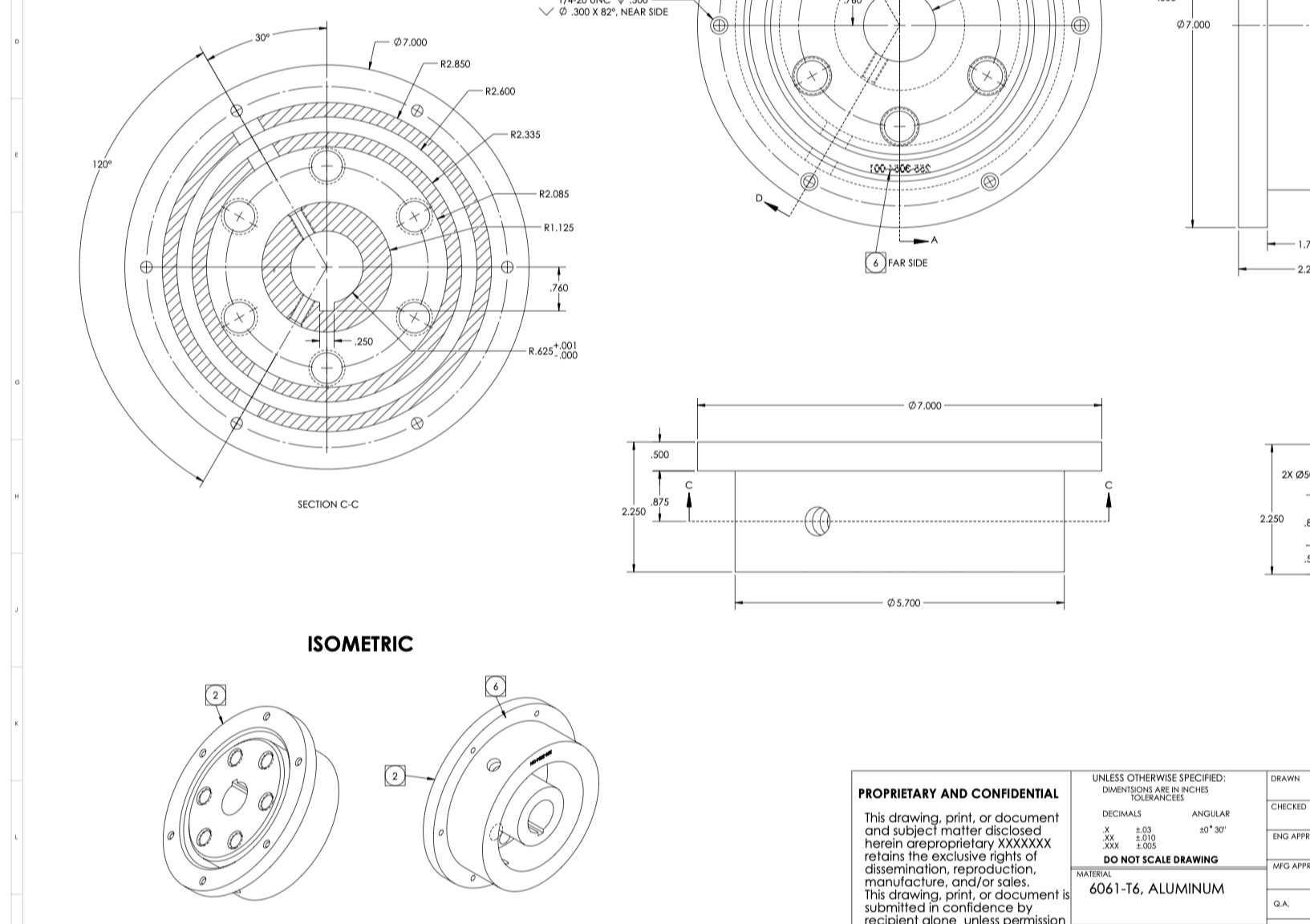

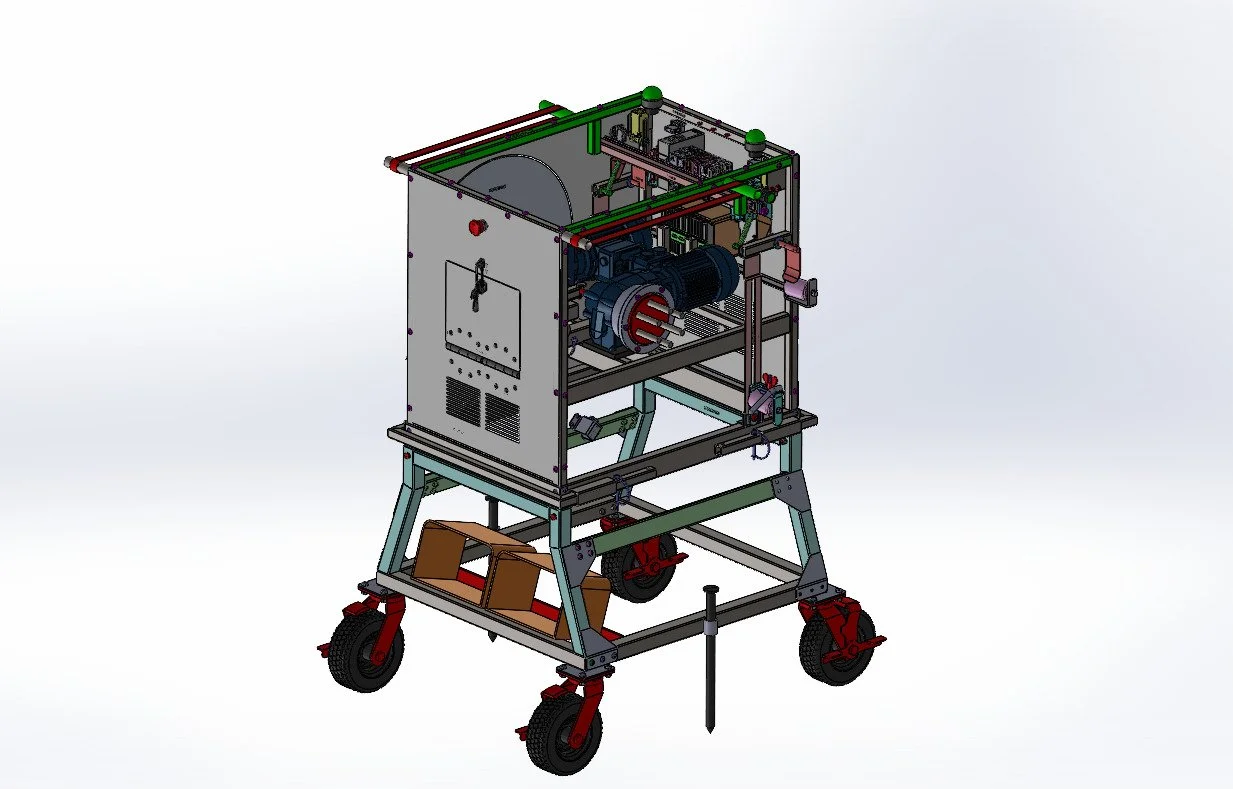

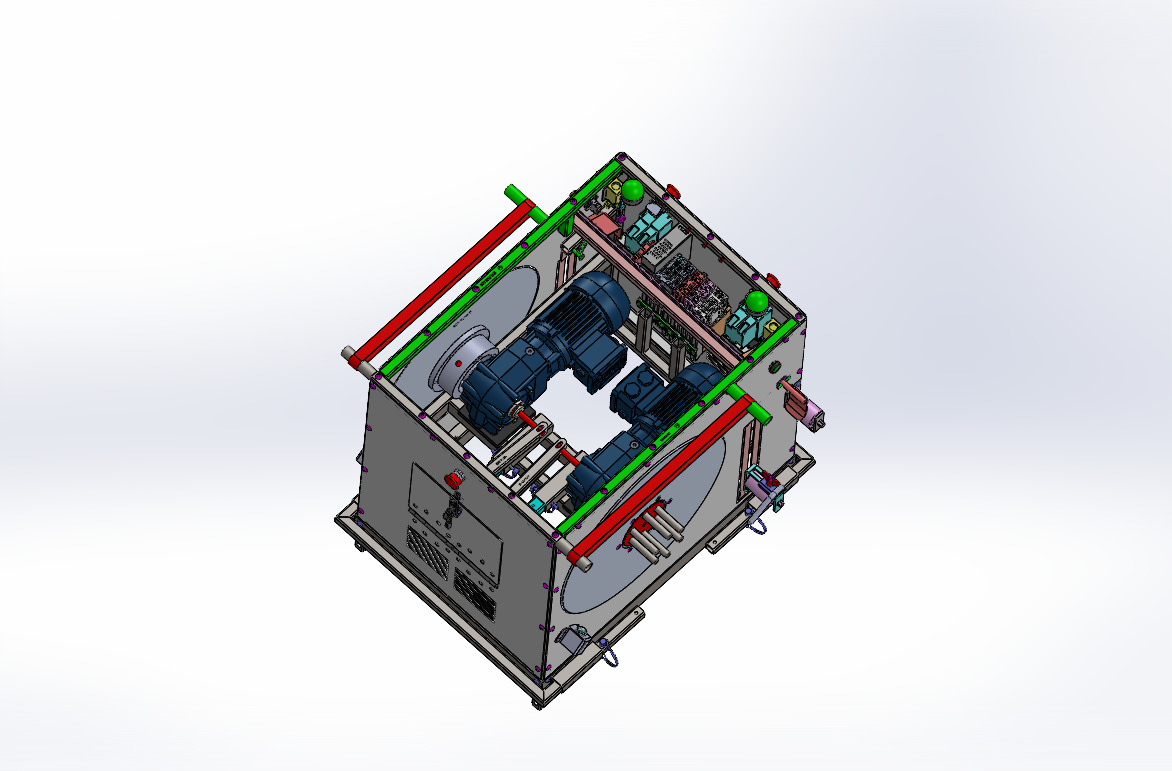

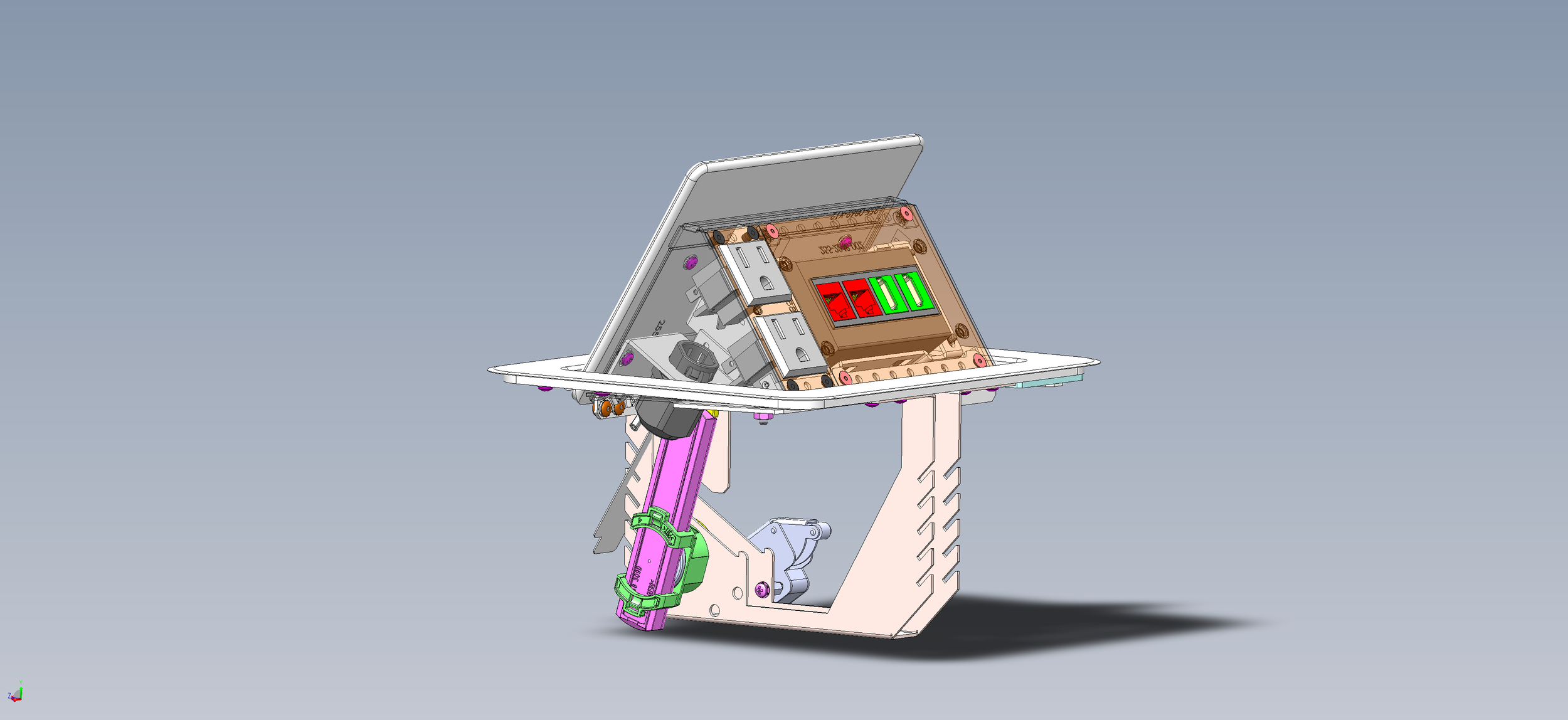

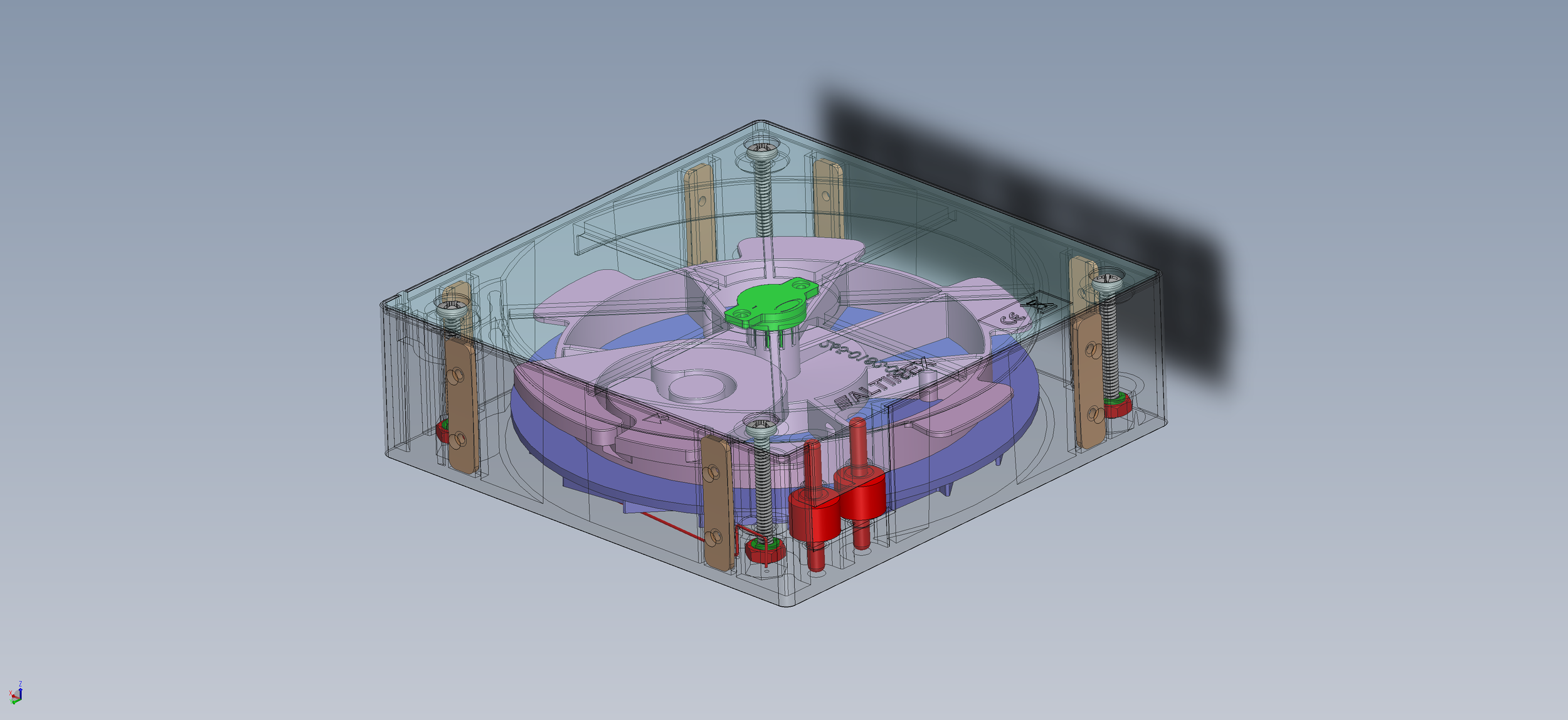

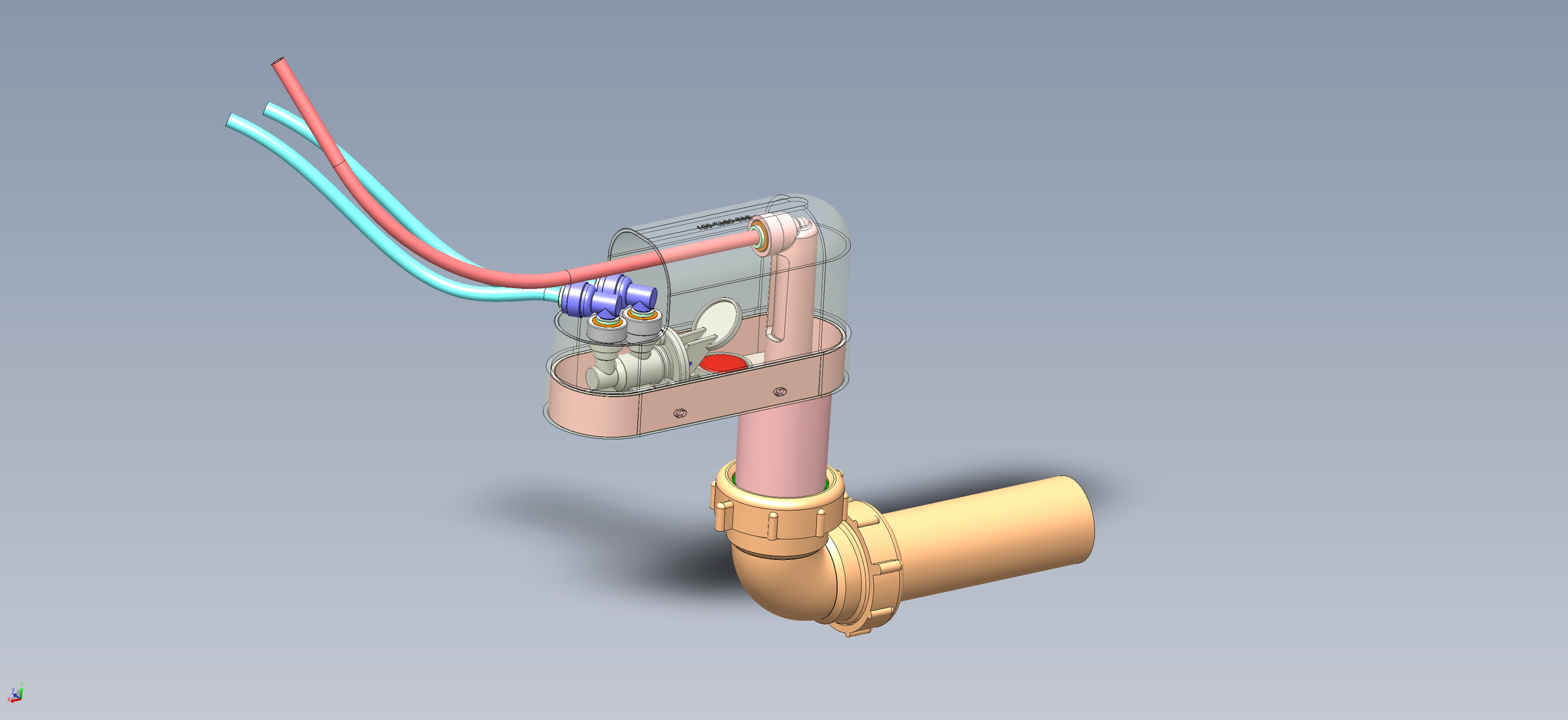

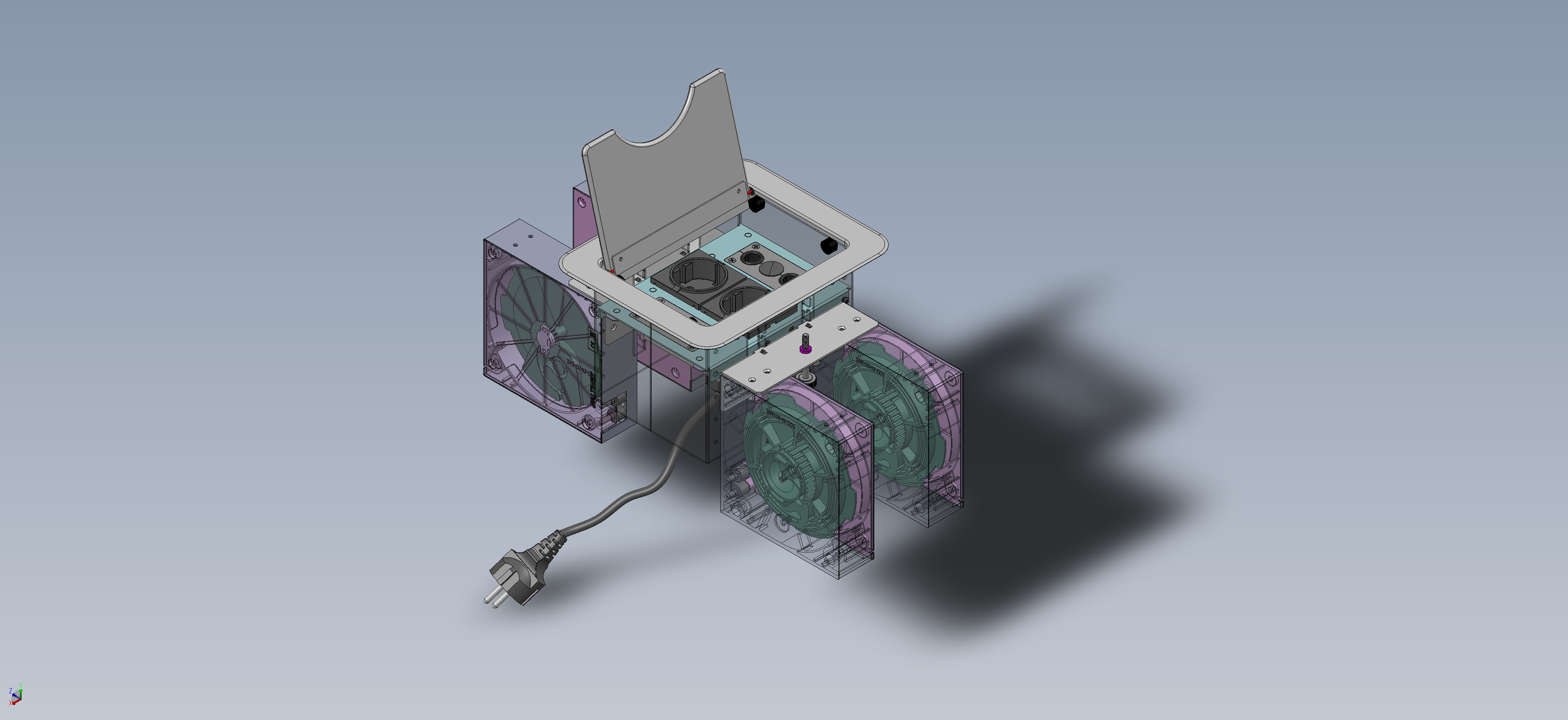

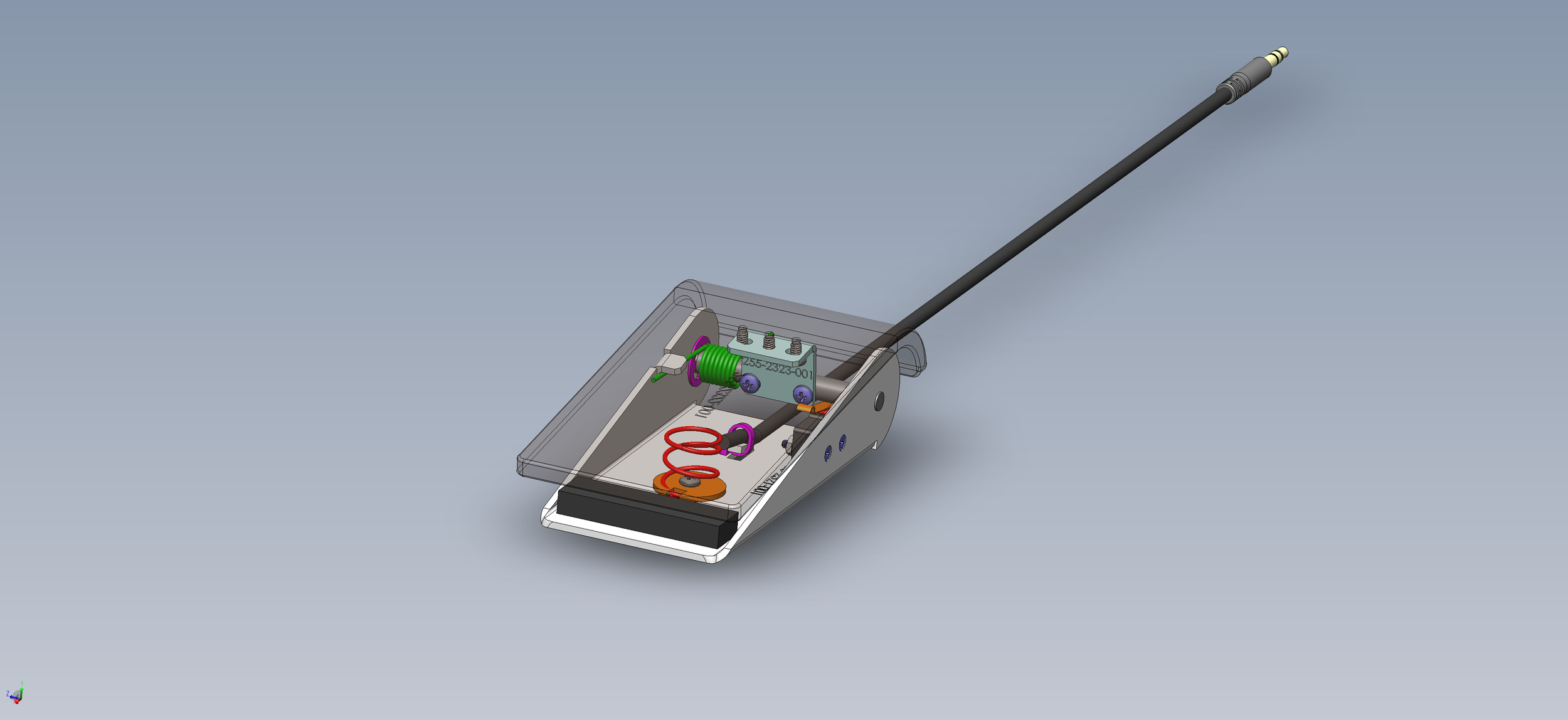

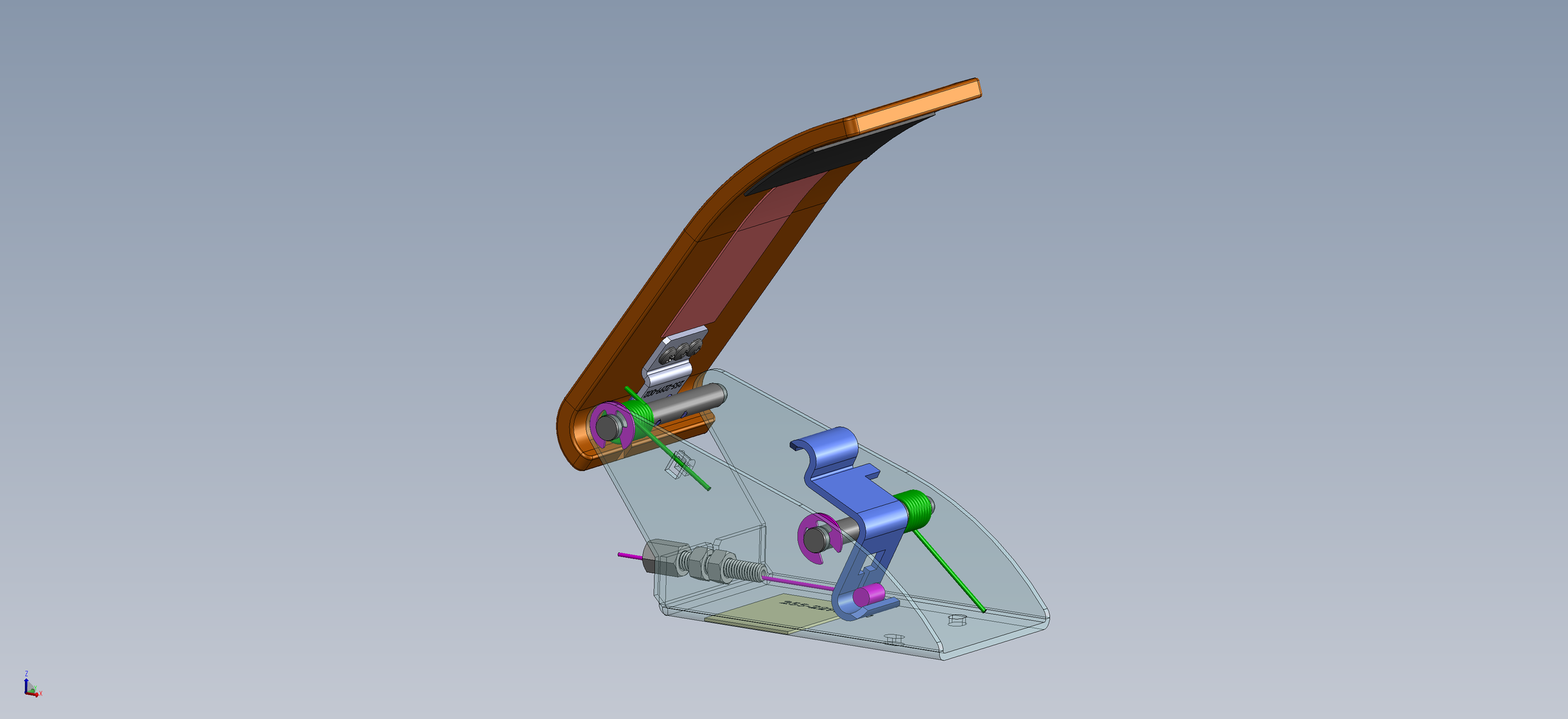

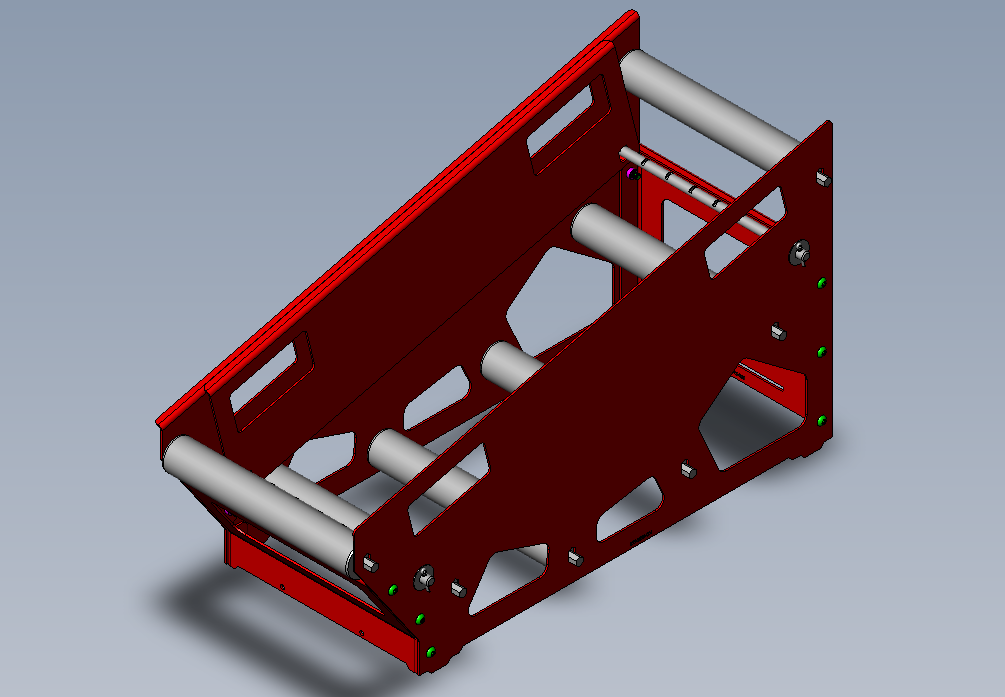

DOUBLE ELECTRIC FIRE HOSE Roller

The challenge

Design a mobile machine capable of rewinding two fire hoses simultaneously for two operators. The equipment needed to be assembled from separate modular parts for easy customer assembly and compact shipping. It had to ensure uniform rewinding speed, meet strict safety standards, shut off automatically at full rewind, and feature both automatic and mechanical hose ejection systems. Additional requirements included a hose tensioning mechanism, visual indicators for operation, pause, and emergency stop, foot-pedal controls, and the option for emergency shutdown.

The solution

The machine was built on welded steel frames made from square and rectangular tubing, ensuring strength and stability. Rotating components were CNC-machined from aluminum, while the housing was fabricated from sheet aluminum for durability and reduced weight. Speed sensors maintained uniform hose winding, and electro-actuators enabled automatic hose ejection, supported by a backup mechanical system. A controller managed operating modes with clear visual indicators, while the entire mechanism was specifically engineered for effortless assembly using only screws and a screwdriver—making it compact for shipping and quick to put together straight out of the box.

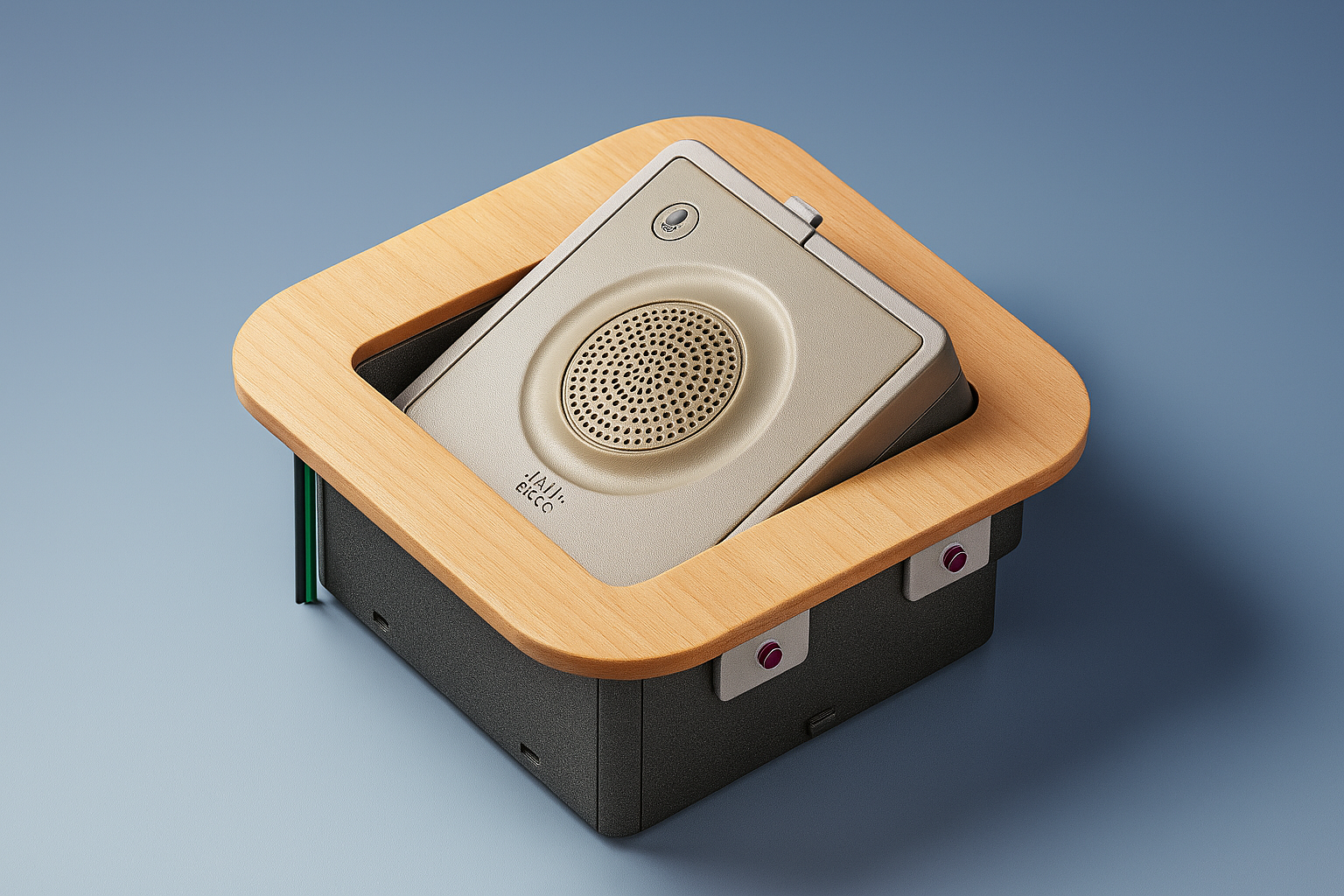

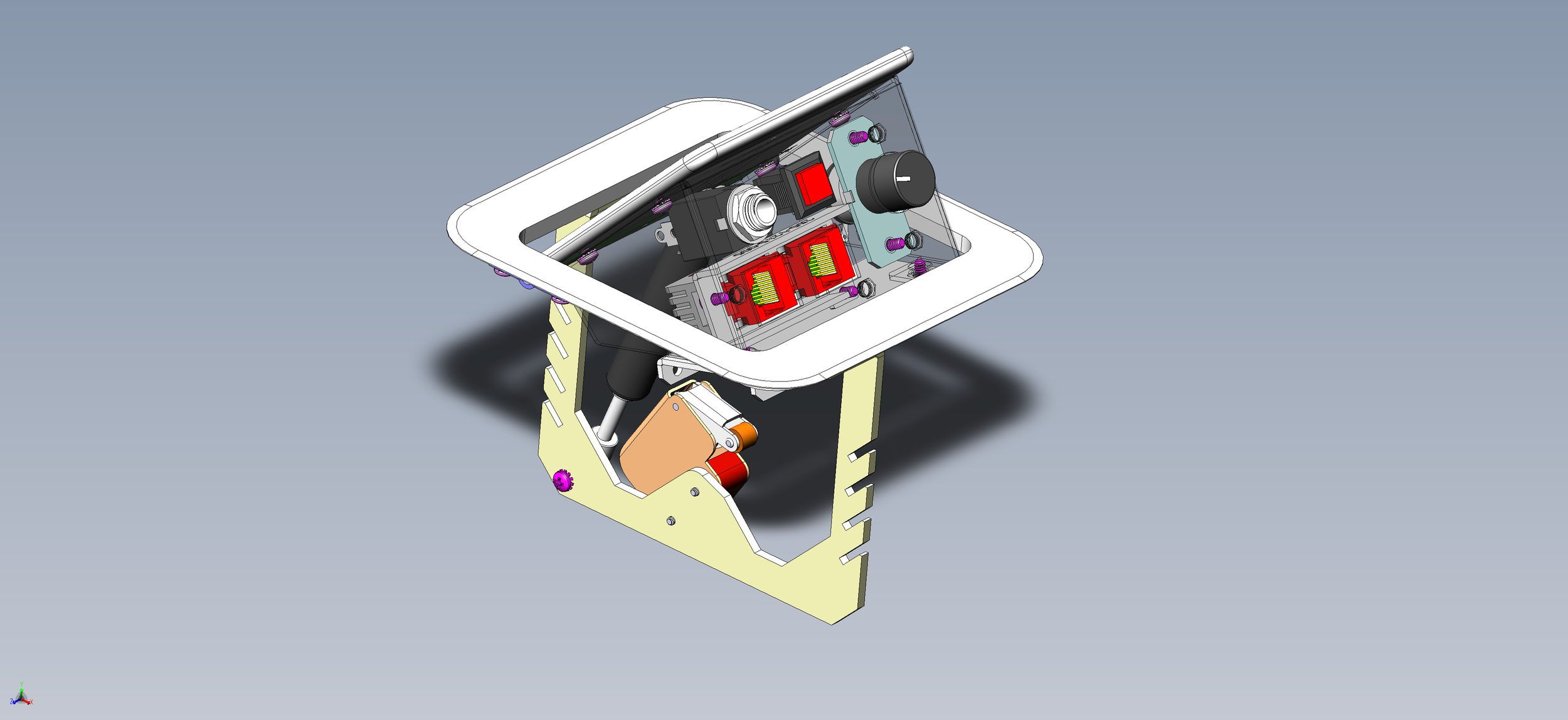

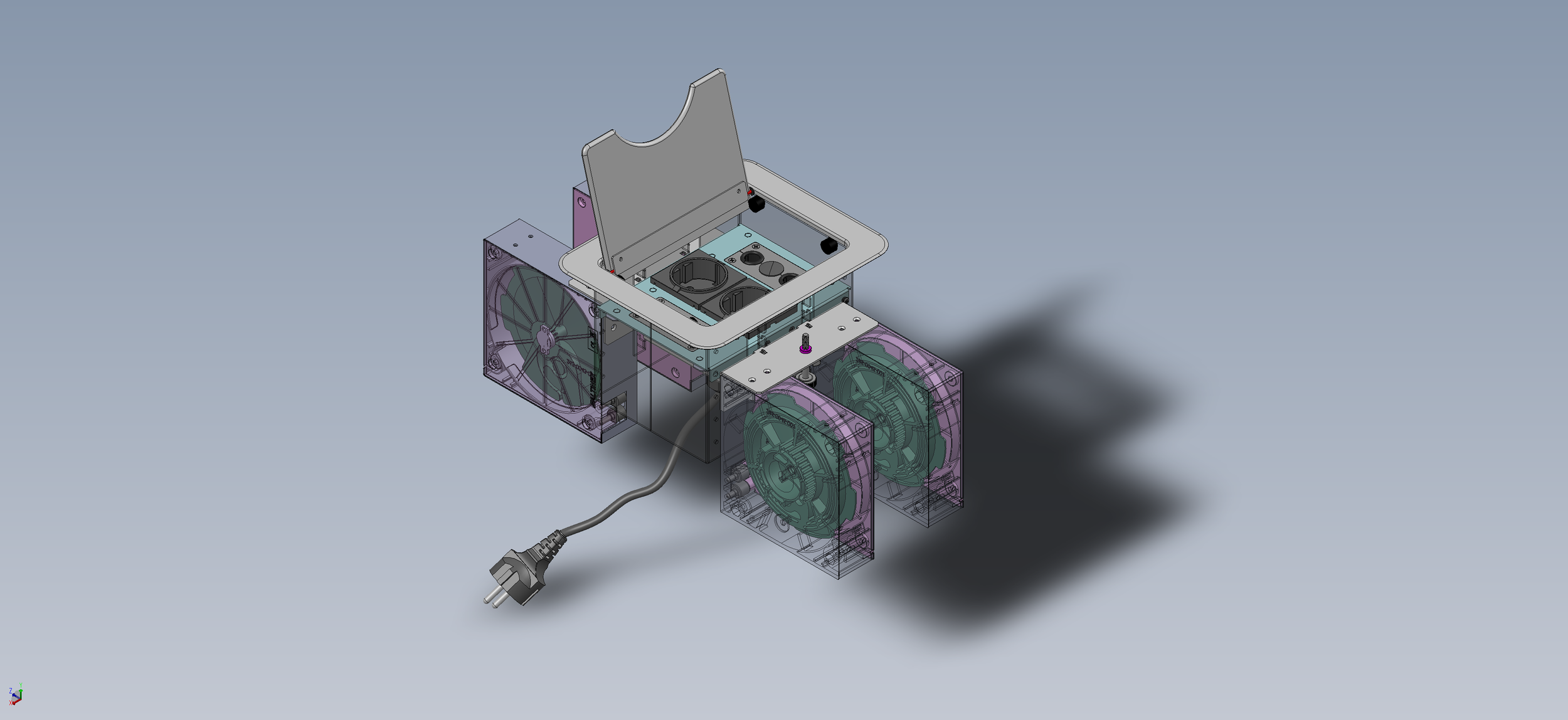

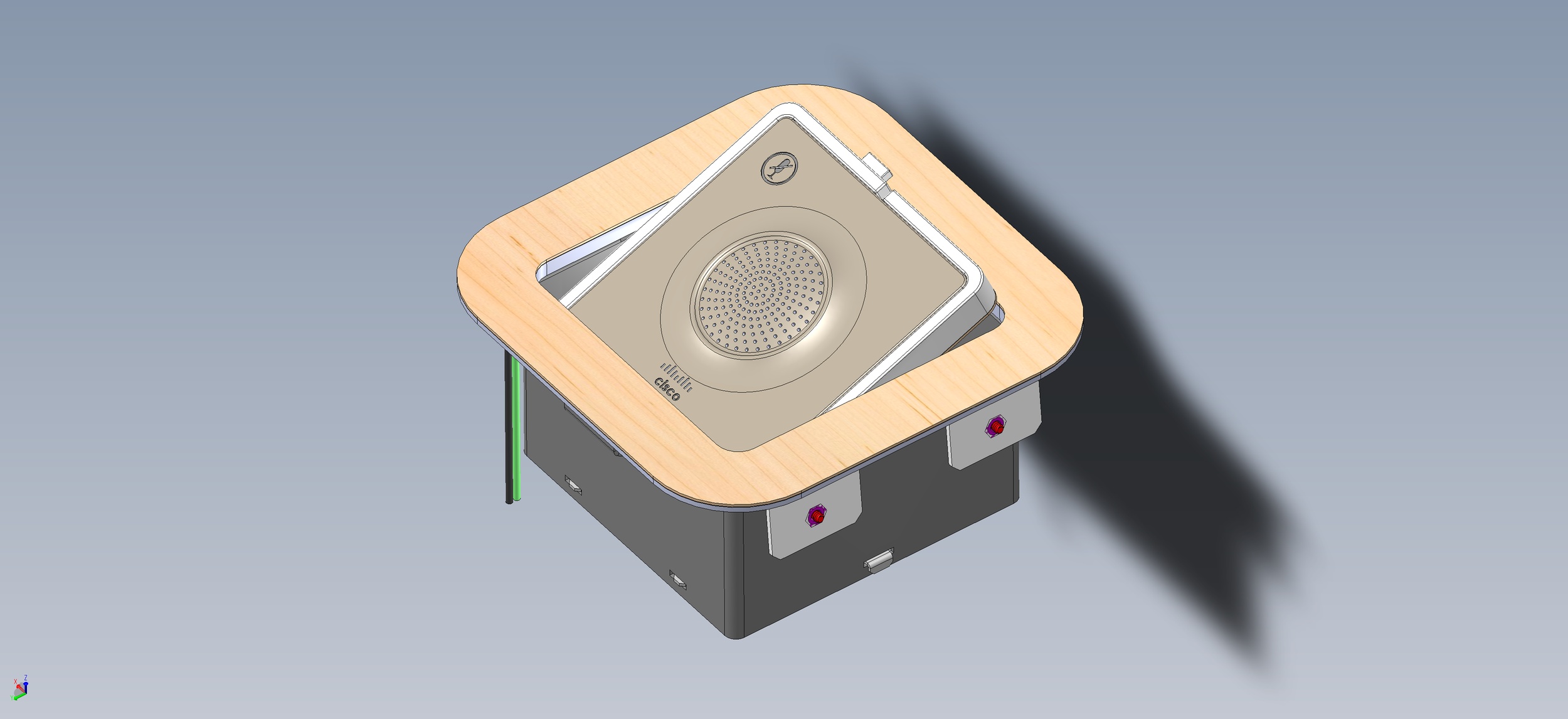

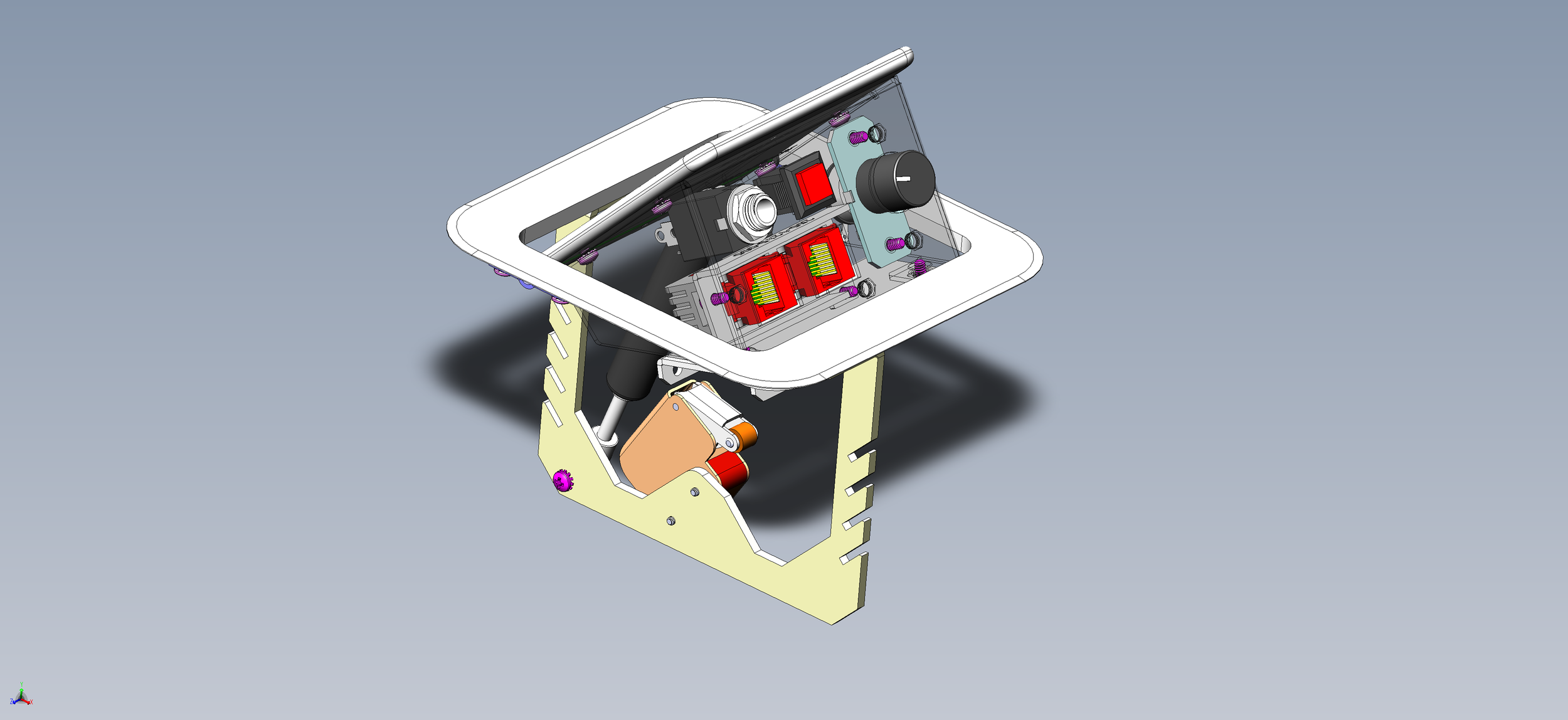

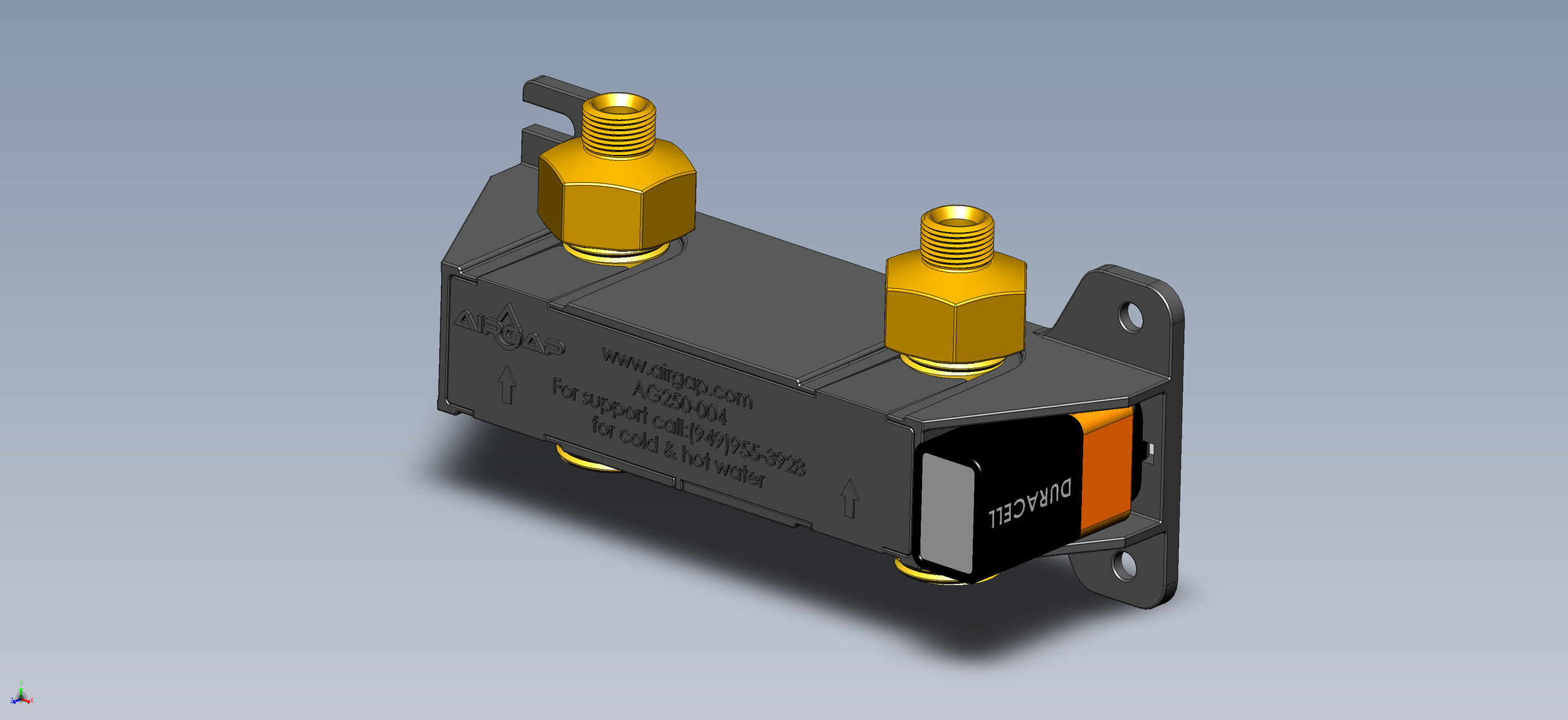

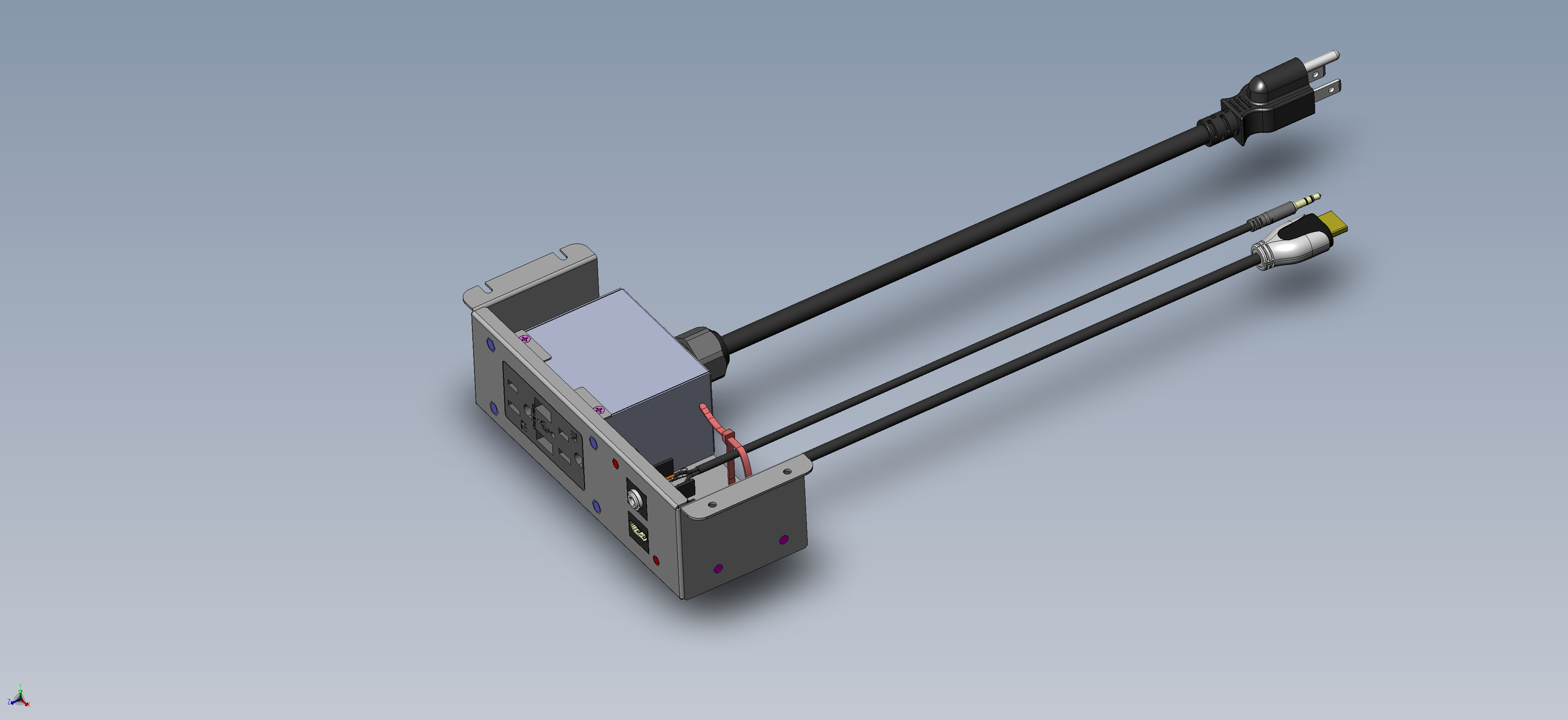

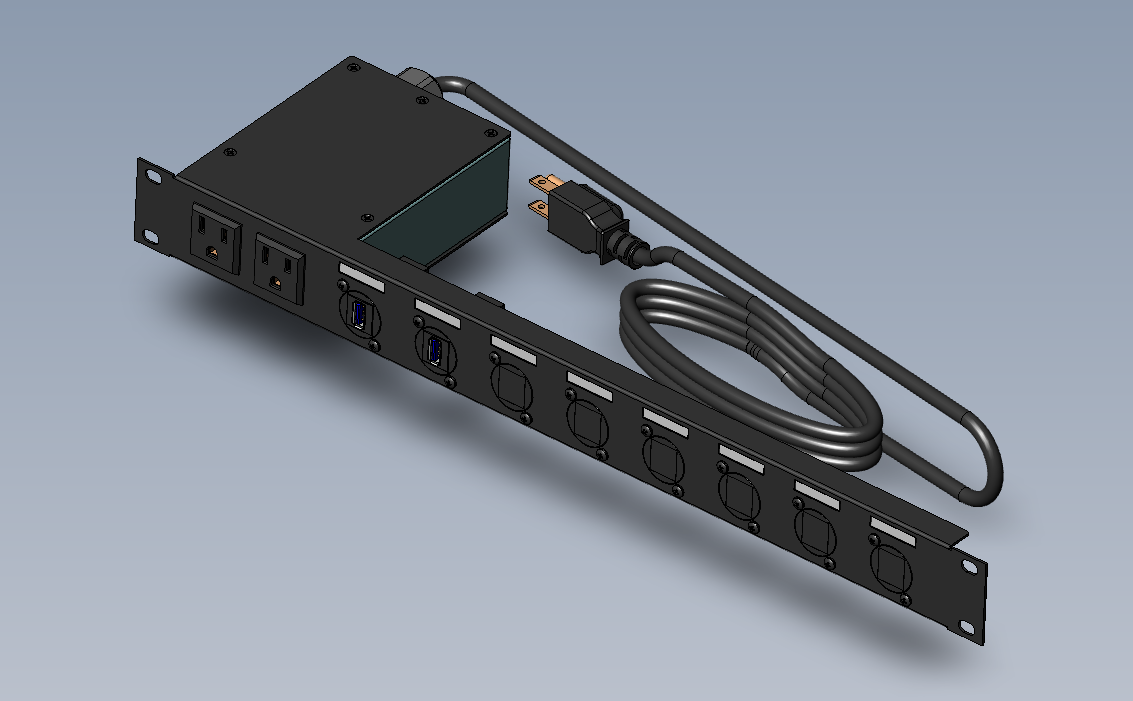

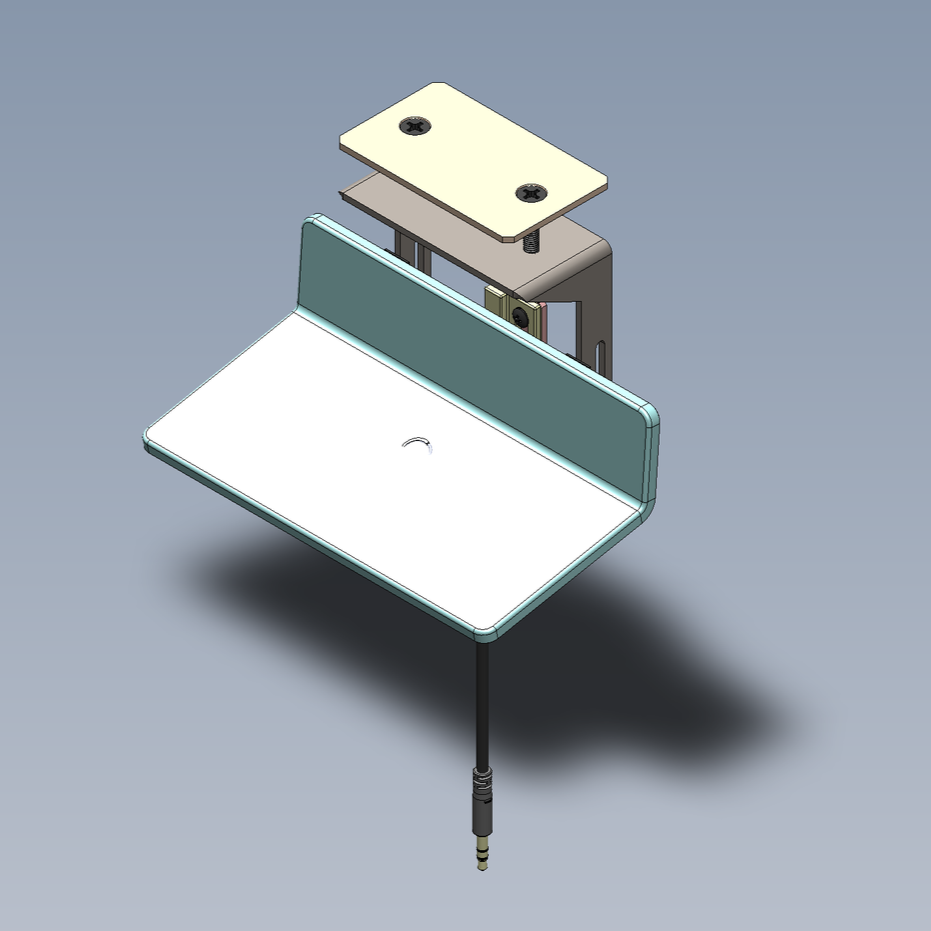

Configurable conference table module

The challenge

Design a modular conference table connectivity module that could adapt to different meeting needs while maintaining a sleek, unified appearance. The unit had to support durability, seamless integration of power and data connections, and allow simple installation or reconfiguration without compromising reliability or aesthetics.

The solution

Developed a flexible, modular connectivity module with interchangeable components and concealed cable management, enabling rapid adaptation to various conference setups. Precision-engineered housings and high-quality plastics ensure rigidity and longevity, while a minimalist design keeps the table surface clean, professional, and clutter-free.

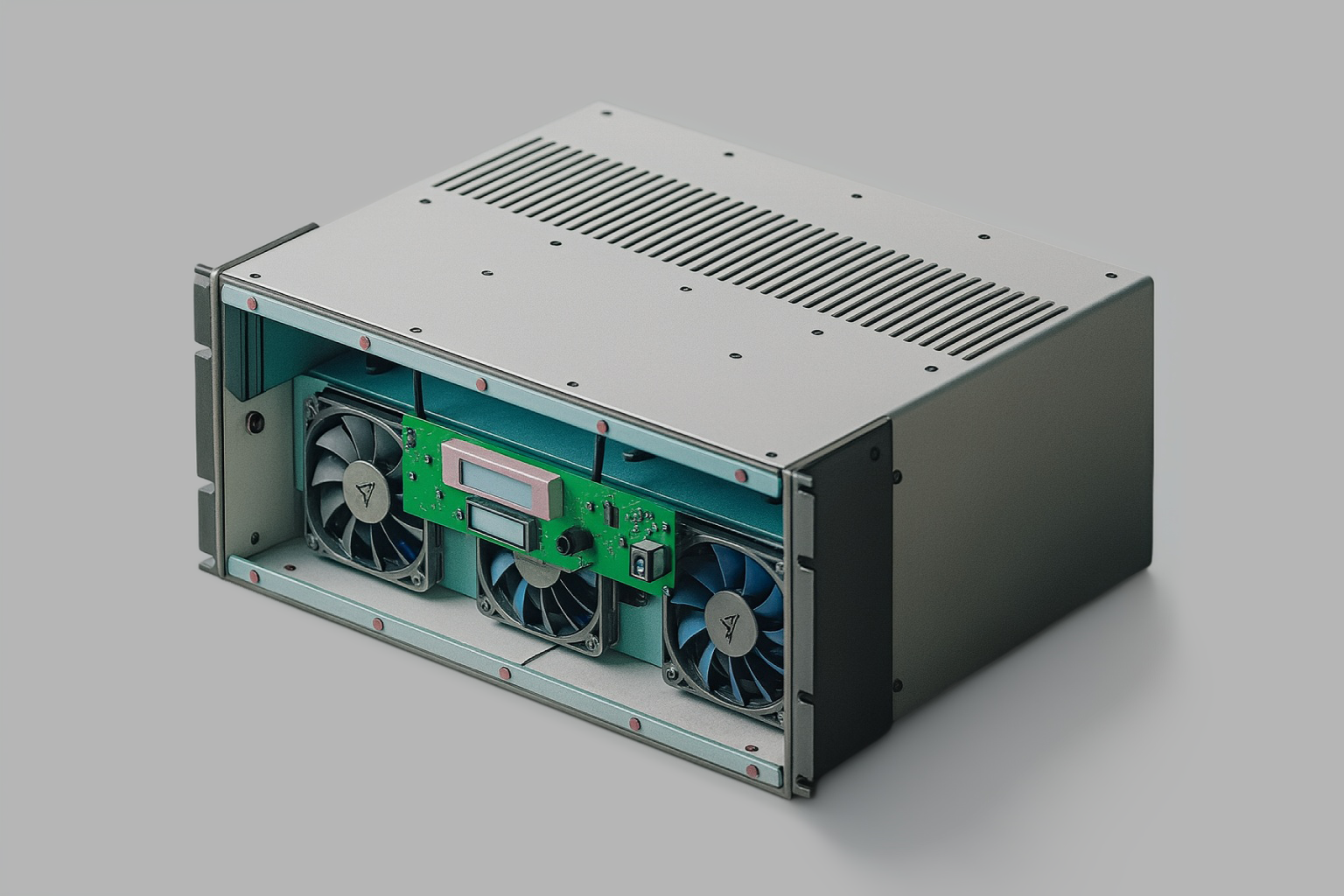

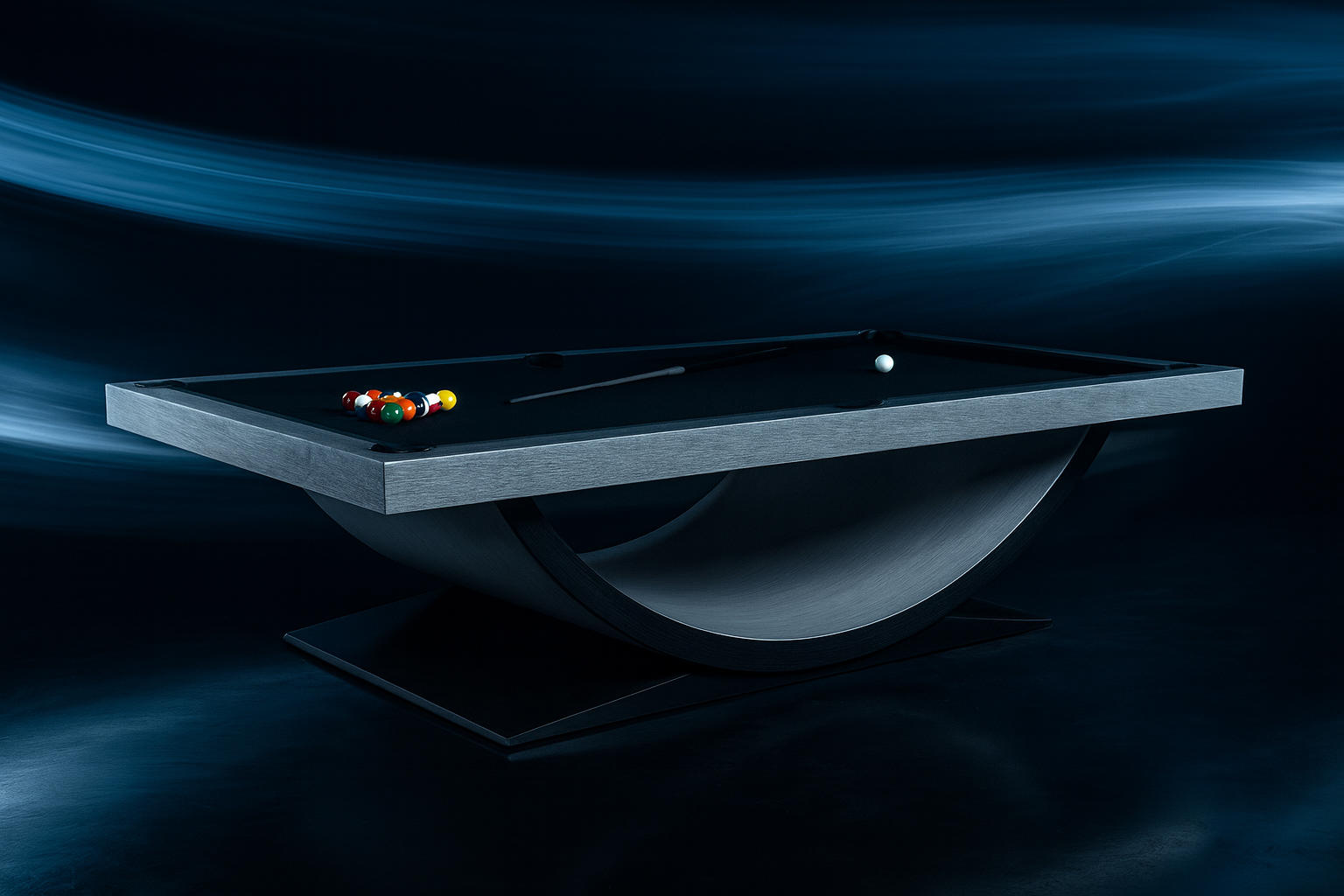

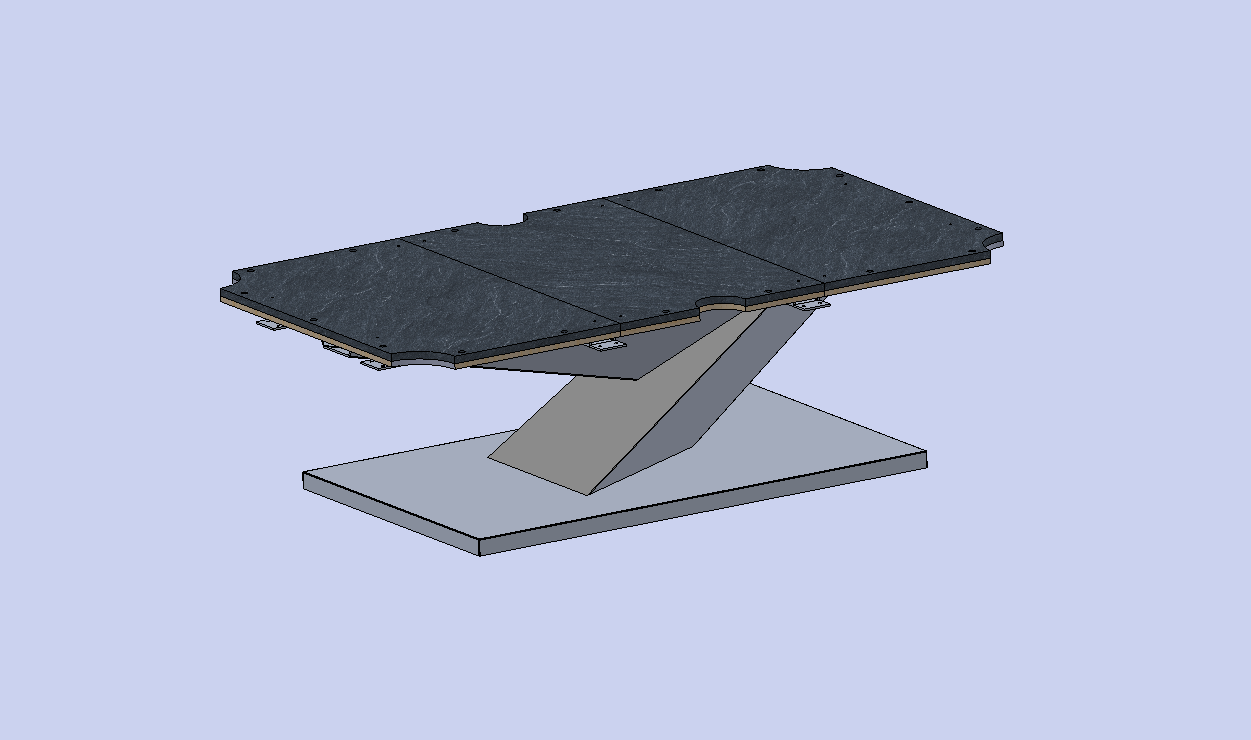

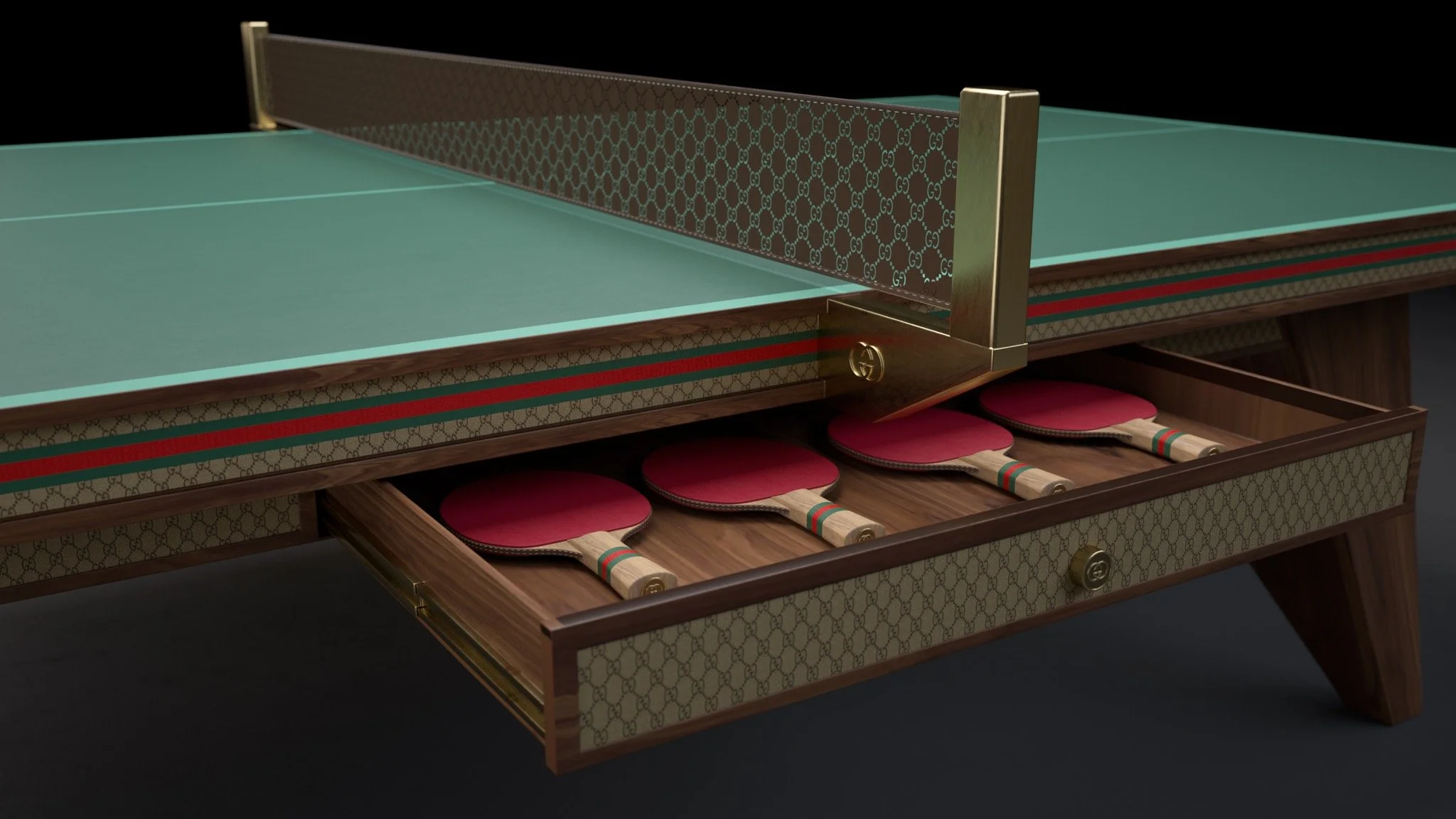

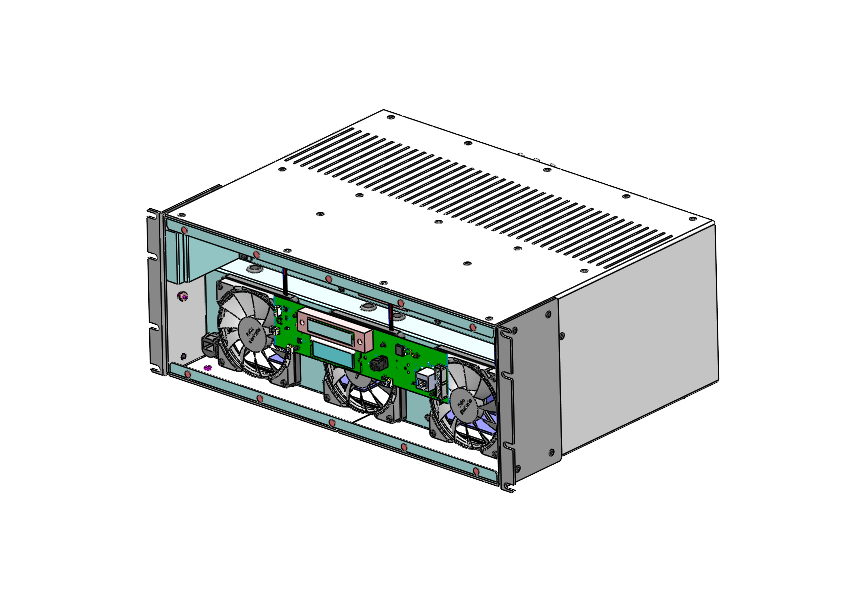

The Pool Tables

The challenge

Design and engineer an 8-foot billiard table based on a concept sketch, ensuring exceptional stability and safety. The table had to support a playing surface weighing 800–850 lbs (363–386 kg) without deflection, maintain a rigid, vibration-free frame under lateral or vertical impact, and meet high aesthetic standards.

The solution

The frame was precision-formed from 1/4" (6.35 mm) aluminum sheet, validated with Finite Element Analysis (FEA) in SolidWorks to ensure zero deflection under load. A welded rectangular aluminum tubing support structure provided maximum rigidity, while a high-quality natural wood finish delivered a refined, elegant appearance.

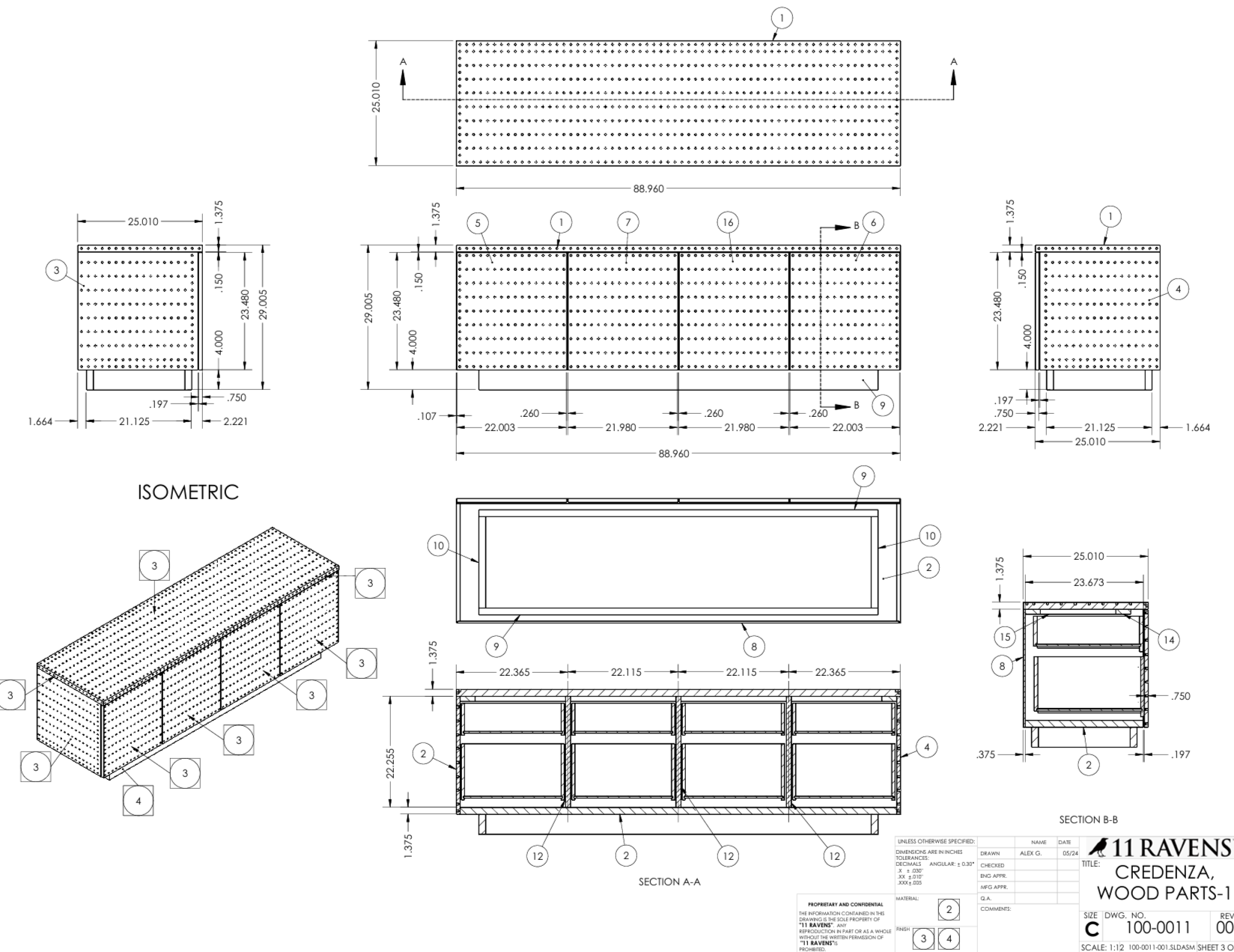

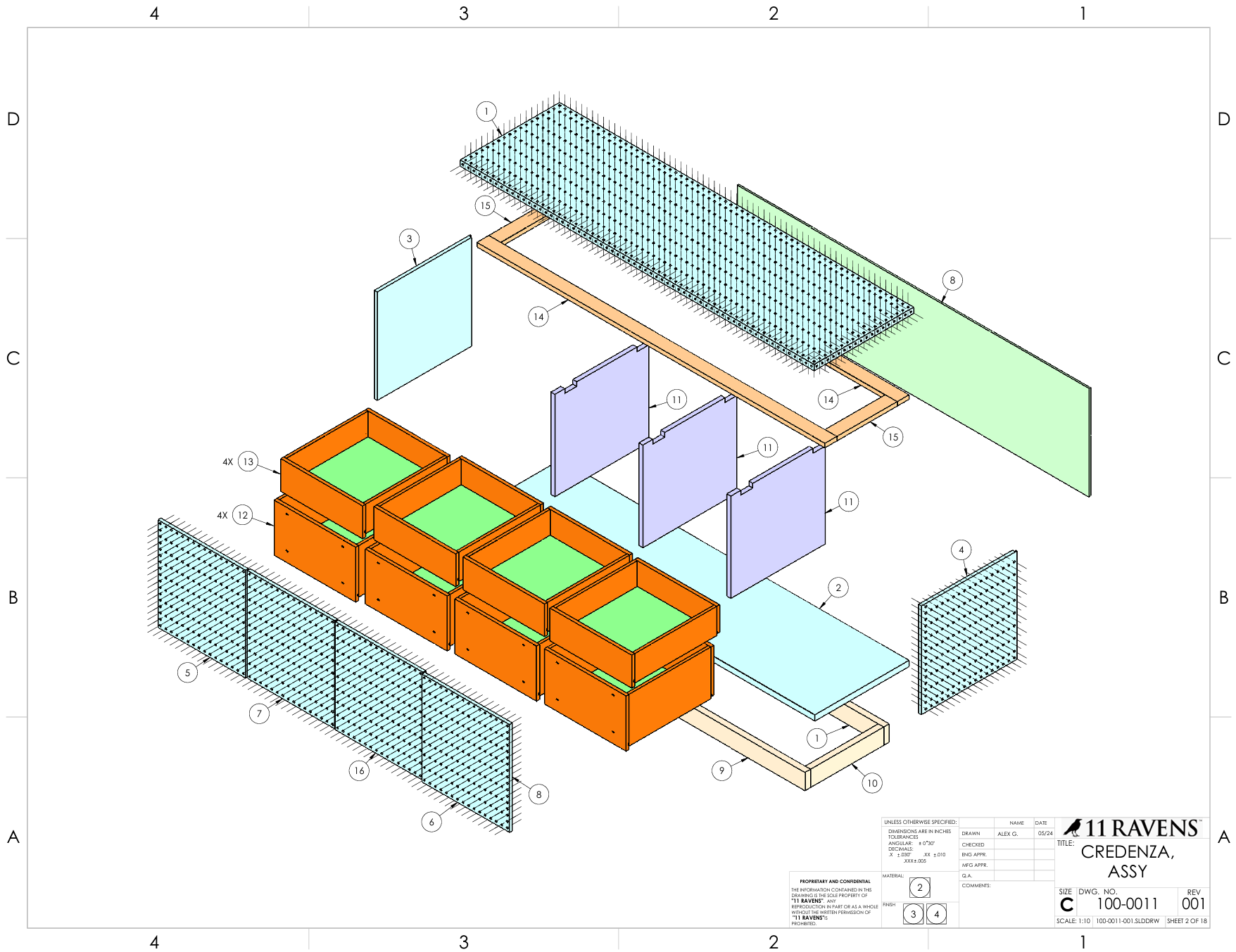

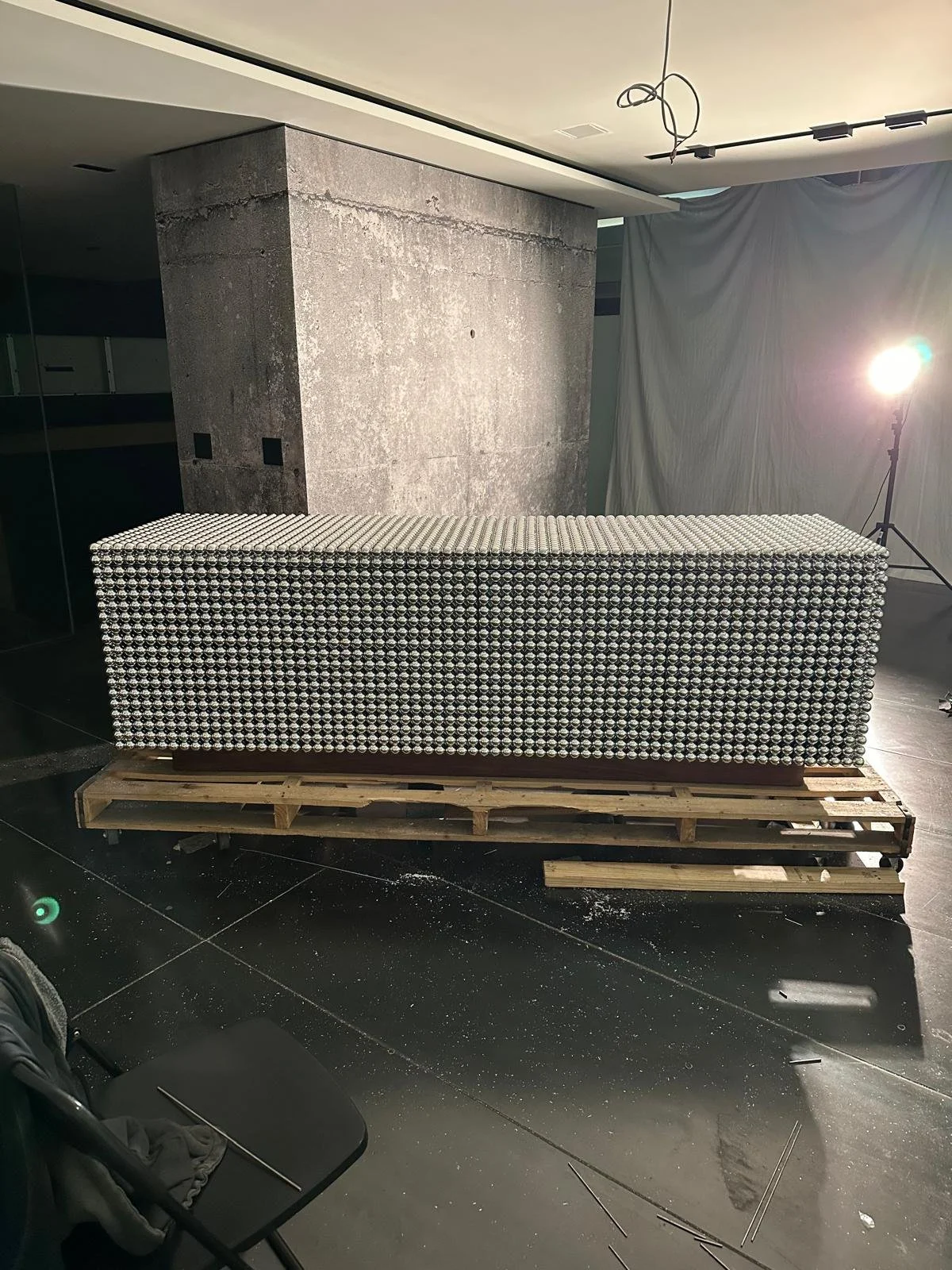

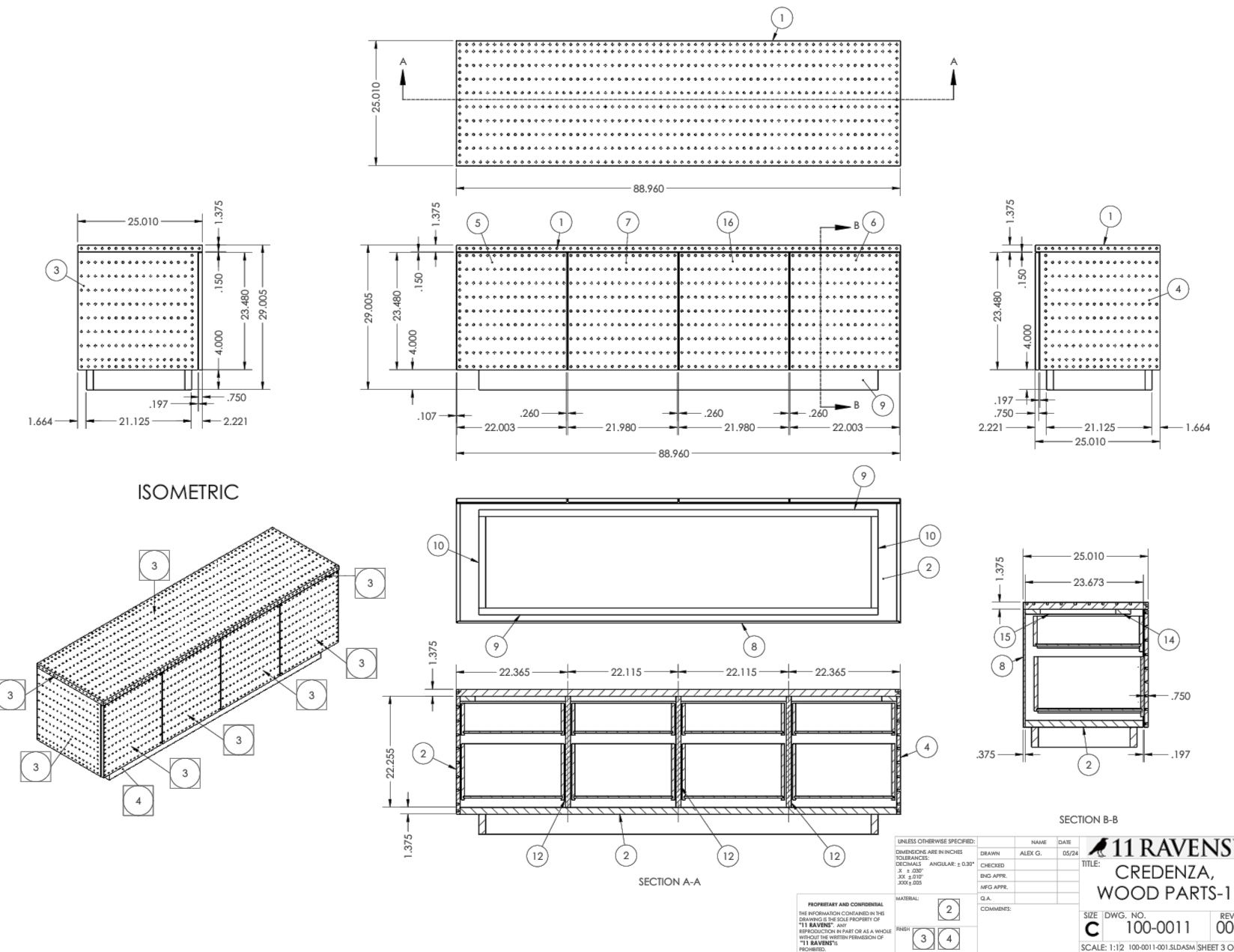

Sculptural Credenza

The challenge

Design a luxury credenza composed entirely of individual chrome spheres, creating the appearance of a seamless, monolithic piece. The four front doors had to remain completely hidden, while the design had to accommodate over 3,200 spheres with precise assembly tolerances of just 0.005 inches, despite the weight and complexity of numerous fasteners.

The solution

A solid wooden frame veneered with mirrored aluminum provided the structural base, while PVC spheres were injection-molded and finished with a reflective chrome coating. This approach delivered a visually seamless, high-end piece that combined meticulous engineering with striking luxury aesthetics.

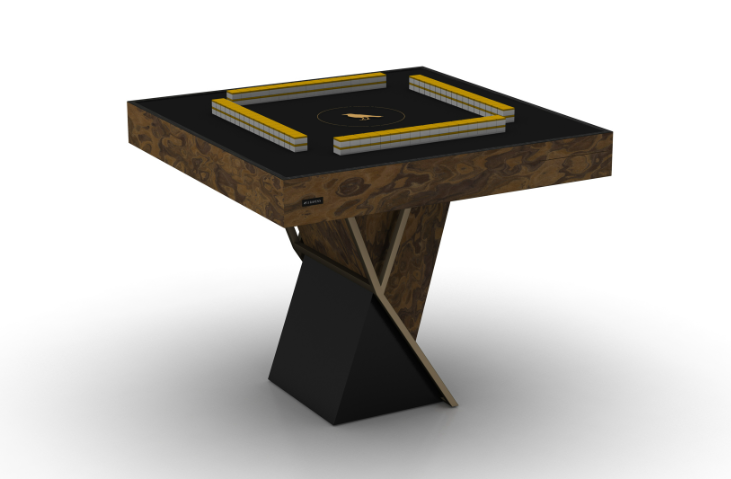

Engineering Projects

privet

(pronounced "pree-vyet")

This means hello in Russian.

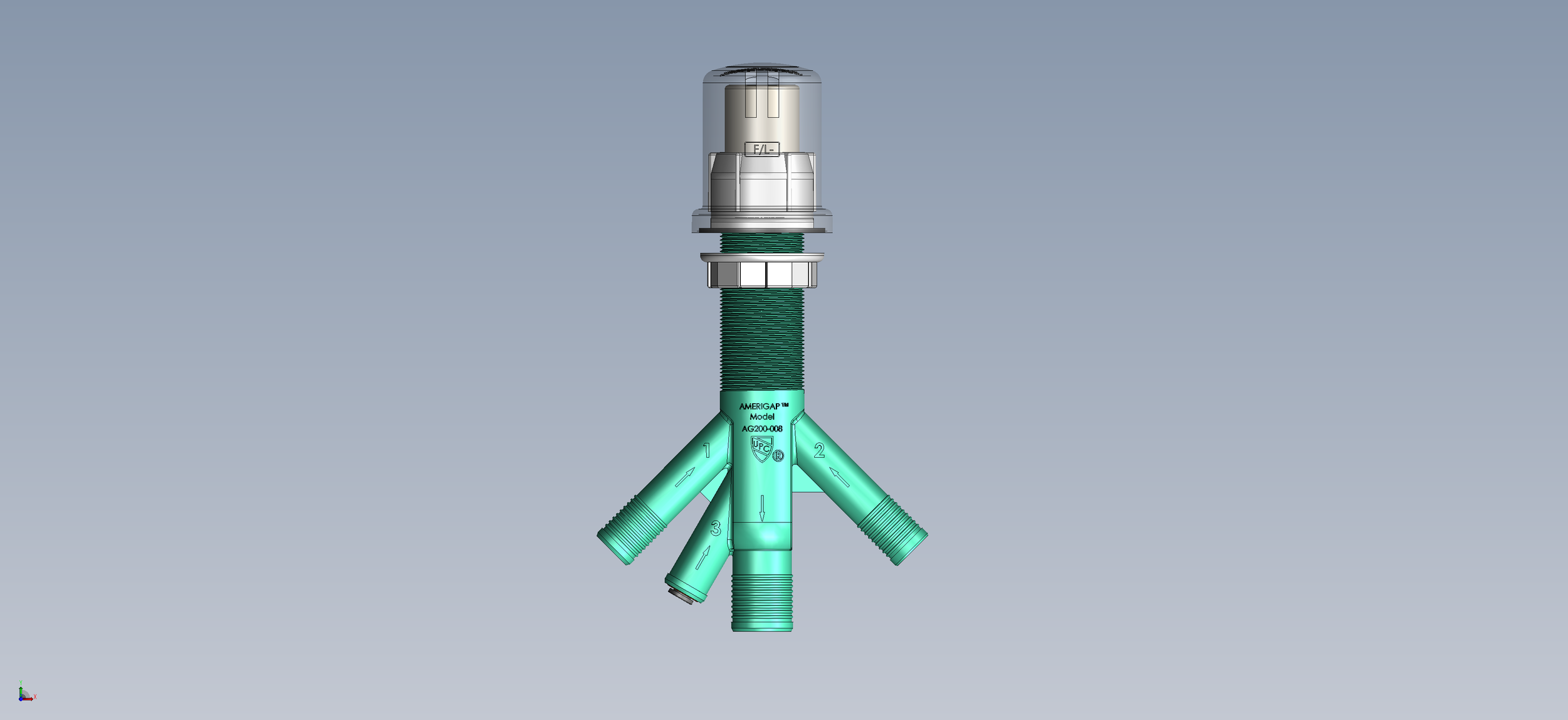

I’m Saveliy Gershfeld, an experienced engineer with over 30 years in construction management and 12 years in industrial and mechanical design. A graduate of the Moscow Civil Engineering University (1982), I advanced from site engineer to executive director of a major construction company, leading numerous custom projects in Moscow and overseeing the Capital Construction Department of a large industrial holding.

Since relocating to the United States in 2012, I’ve specialized in mechanical design and managed to earn a patent and develop a wide range of mechanisms, devices, and products — from office communication equipment and veterinary tools to fire department gear, high-end pool tables, packaging, and even luxury furniture for “Eleven Ravens” (www.11Ravens.com).

Today, I run my own design business, offering 3D modeling, CAD, and full product development services from concept through manufacturing. My approach is simple: work honestly, communicate openly, and deliver on time — ensuring every client is fully satisfied.

Let’s build something great together!

Interested in working together?

Fill out some info and attach any sketches or designs of your product for initial estimation and I’ll be in touch shortly.

Can’t wait to hear from you!